Headseaway has rich experience in crating and lashing OOG cargoes, and has formulated strict operation specifications, and has strict standards for cargo loading and discharging lifting tools and the use of lashing materials to ensure that customers' cargoes are always in safe condition during transit.

How to make a packing plan for OOG cargo?

Distribution safety principles, (cargo weight pressure evenly distributed at the bottom of the container, consider the center of gravity of heavy cargo as much as possible in the longitudinal and transverse cross center of the bottom of the container).

Container volume and load full use of the principle, (single container as much as possible, reduce the number of containers used).

Consider the special container on the cargo weight limit requirements, strictly prohibited to exceed the weight limit.

The principle of reducing freight costs (the same size, loaded together, light and heavy goods reasonable collocation).

Consider the requirements for overload and overweight when transporting cargo outside the country.

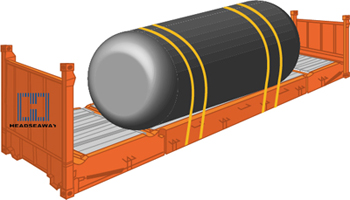

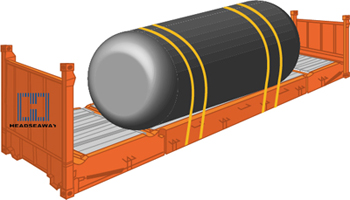

How to carry out protective measures when loading OOG cargo in special containers?

When the cargo securing wire rope and cargo contact surface padded with plastic sleeve.

Covered with canvas according to customer's requirements.

For bare goods with high requirements for appearance protection, try to use lashing tape.

For contact between metal goods, use rubber mats for separation to prevent friction.

Lashing material standards and securing specifications

1)The principle of effective lashing and securing between the cargo and the container is to prevent the cargo from tipping to the sides of the flat rack container and sliding towards the ends (baffles) during lifting and navigation of the OOG, which could lead to damage of the cargo. 2)It is forbidden to put one end of the flat rack container (Rack) upright and one end down, both ends must be upright or down at the same time. 3)The goods should be evenly discharged on the wooden floor of the flat rack container according to the weight, do not bias the weight to one end, prevent the goods from tipping to both sides and sliding longitudinally by tying and wooden wedges, and lower the center of gravity for the large goods with high center of gravity. 4)The cargo and the flat rack container floor need to be padded with sleepers to increase the friction coefficient, and the cargo and the flat rack container need to be filled with support between the two ends of the baffle to prevent longitudinal movement.

|

|

5)Prohibit cargo and securing tools from blocking the four Corner Casting of the flat rack, i.e., lifting points; keep at least 30 cm gap between cargo and flat rack baffle, lashing and securing standards otherwise the dock machinery cannot be lifted. 6)The load on each securing point on both sides of the flat rack is usually 5 tons, and lashing should be avoided to concentrate on a particular securing point. 7)Prohibit the use of nails to nail sleepers or wooden wedges into the wooden floor of the flat rack to avoid damage to the flat rack and reduce its load-bearing strength. 8)Wire rope or nylon ties for lashing must be kept fully tensioned, and the wire rope must be equipped with a flange turnbuckle, and the nylon ties must be equipped with an anti-reversal ratchet. 9)lashing with steel wire rope or nylon ties and the edge contact point of the goods need to add padding, padding layer should be selected from plastic materials (prohibit the use of carton type); shaft, rolled steel goods perforated wire rope and the edge contact point of the goods need to set plastic tube as a padding. 10)For the platform contains the frame ends of the baffle down, because the lifting point (i.e., Container Corner Casting) by the ship's cabin Cell guide obstruction, according to international norms, in principle, can only accumulate on the ship's deck.

|

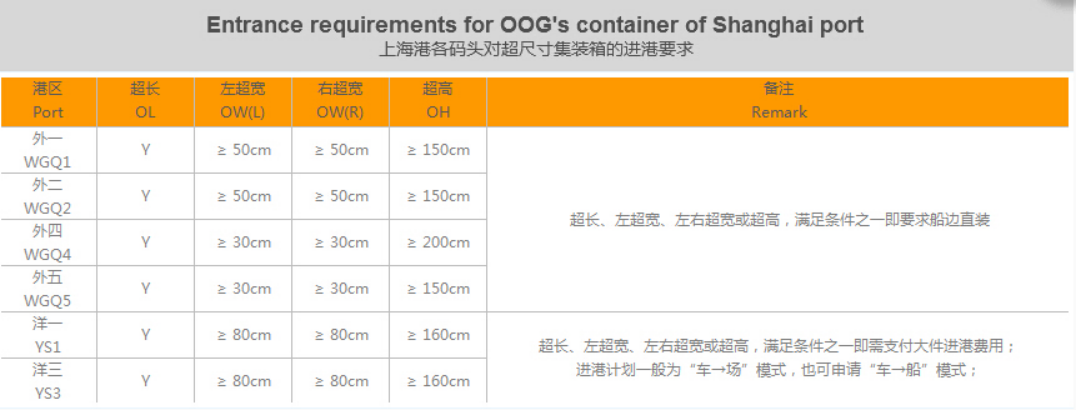

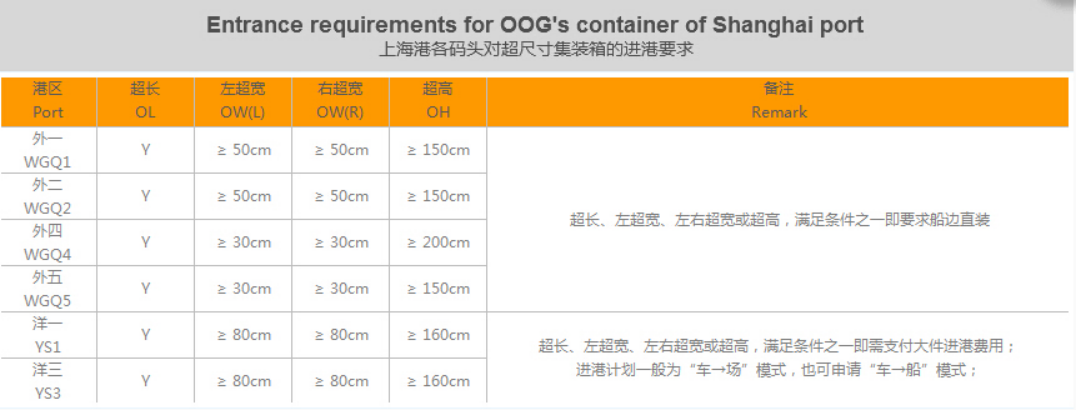

Entrance requirements for OOG’s container of Shanghai Port.

Diagram of lashing and securing operation example